The Importance of cone crusher wear parts

Aug 28, 2024|

Aug 28, 2024| View:29

View:29Cone crushers are necessary in most industries, especially in the mining and construction which must crush different sorts of material. However, these machines are very efficient and produce high quality aggregates. Which, of course is true as with all heavy machinery the attachments need regular upkeep and replacing wear parts to keep them in performance ready condition. Why Cone Crusher Wear Parts are Important In the case of cone crusher wear parts, whether work-hardening or high Manganese steel you need to select those that fit your unique requirements.

Cone Crusher Wear Parts

Crusher components that are subject to wear during the crushing process Cone crusher Wear parts The material is crushed by compressive forces between the mantle and the bowl liner. With time, these parts wears out since the high-effect as well as rubbing of resources being actually processed. The most common

cone crusher wear parts include:

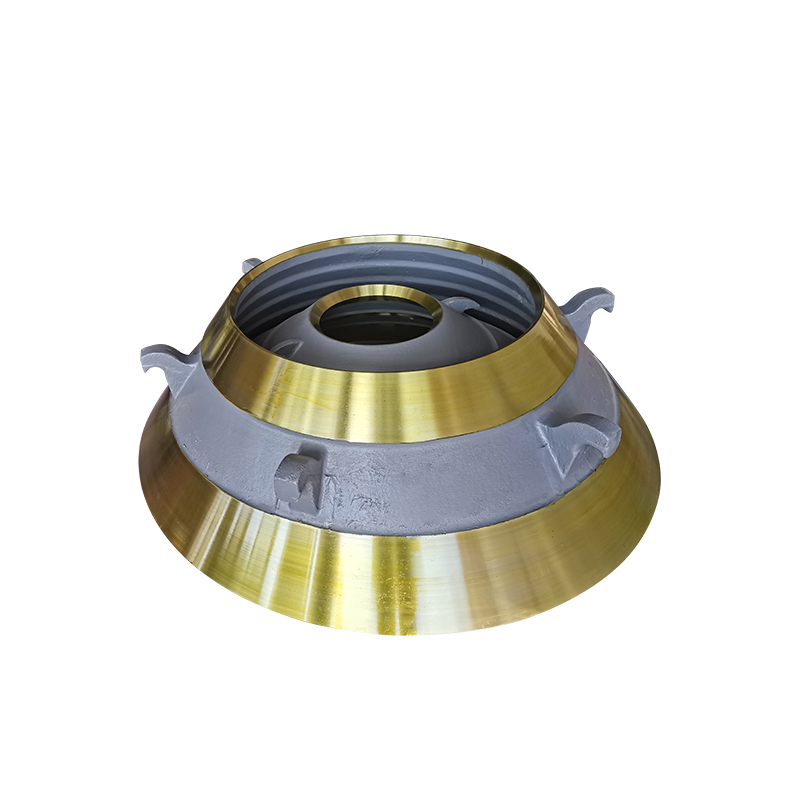

Mantle: The mantle gyrates within the bowl provided by the stationary bowl liner. It is specifically designed to waylay material by compression into the walls of bowl.

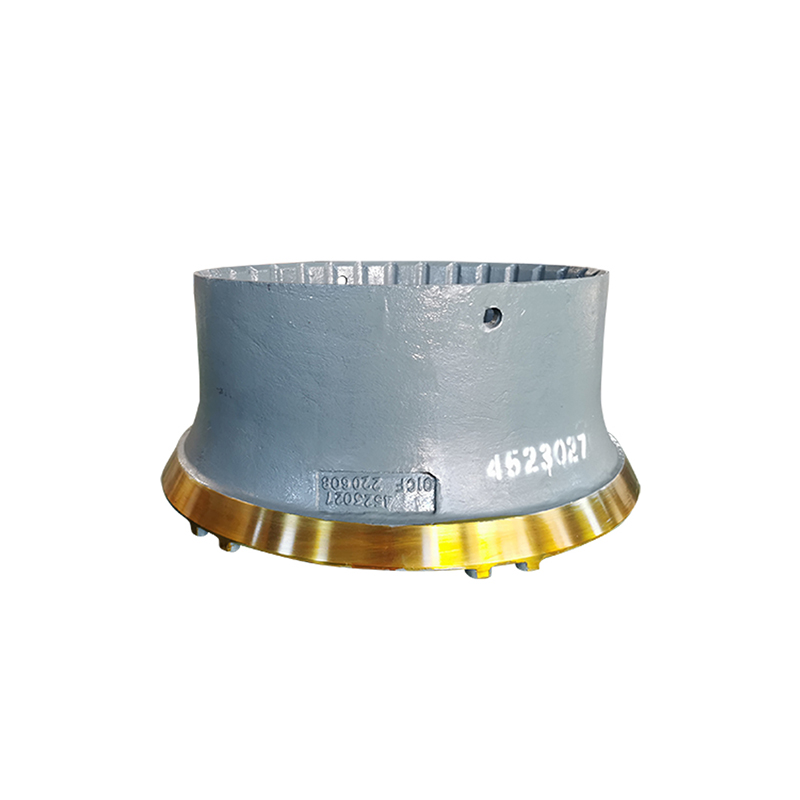

Bowl Liners — This what you place between the mantle and jaws, made of solid material. They serve a feed through surface material being struck.

Cone Liners : ConeLiners refers to both the mantle and bowl liner respectively.

Miscellaneous Parts: Spacers, bushings and mantles' retention systems are all components working together to ensure that it runs efficiently.

The Importance of Wear Parts

The cone crusher wear parts need to be changed in a timely manner. Quality Wear Parts

Constant Product Size – properly working wear parts guarantee the length and form of final goods that conform to your ready standards.

Increased Downtime: When wear parts reach their time limits in use, they often break down without warning. Frequent replacements prevent prolonged downtimes and promote continual service delivery.

Cost Savings: Sewar parts cost operators fewer costs associated with maintenance and improved productivity over several operation intervals.

Reduced Safety Risks: When parts wear out, they are likely to cause mechanical damages and accidents that could cause injury or loss of operating time. Substituting worn-out parts guarantees an operator’s safety during operation activities.

Factors Influencing Wear Parts’ Lifetime for Cone Crushers Material characteristics.

Material properties and crushing size play a vital role in determining wear. Harder rocks such as granite and basalt wear down faster than processed material like limestone.

Operation Conditions. Humidity, temperature, and contamination influence rates of wear. Crushing quality. The method of operation, including the feeding angle and crusher revolutions, influences rate of wear.

Quality materials. Parts quality choice on a manufacturing level. Manganese steel has dense structure and alleviates impact and wear.

Maintenance Practices The following strategies should help prolong cone crusher wear parts’ efficacy: Frequent Inspections.

Routine checks should detect the status of wear and area for substitution. Regular calibration precludes sudden breakages.

Monitoring Wear patterns. Records should gauge wear and help operators set canister widths. Proper lubrication. Regular application lubricates and reduces friction, which, in turn, alleviates wear.

The Right Installation: The correct installation of wear parts matters as well. If left unaddressed, misalignment might result in uneven wear and reduced efficiency.

Access to OEM Parts : Genuine manufacturer parts are compatible and higher quality which means a better fitment, overall performance…

MGS Casting cone crusher wear parts are based on proprietary alloys developed by the MGS of its predecessor long supported manganese and brass netwo Cone crusher wear components, including mantles, conical spacers (also called brief heads), as well as defenses. Operators need to understand the different types of wear parts, what factors can affect how long they last and some simple best practices for maintaining their equipment. The performance of these machines is relied on heavily, enough to make preventative maintenance and a replacement parts program the new rock equivalent choice for staying in top shape. The mining and construction industry is just one of those industries were having a reliable piece of machinery that can handle the strain that this extremely demanding work environment requires, is incredibly important.