Crusher Wear Part Optimization: The Key to Enhancing Equipment Performance

Jul 04, 2023|

Jul 04, 2023| View:260

View:260Crushers play a crucial role in various industries, from mining to construction, by breaking down large materials into smaller, manageable pieces. However, the efficiency and reliability of crushers heavily depend on their crusher wear part optimization. These essential components are designed to withstand wear and tear, ensuring uninterrupted operation and maximizing equipment performance. In this article, we delve into the world of crusher wear part optimization to understand their significance and explore how they contribute to the optimal functioning of crushing equipment.

What are Crusher Spare Parts?

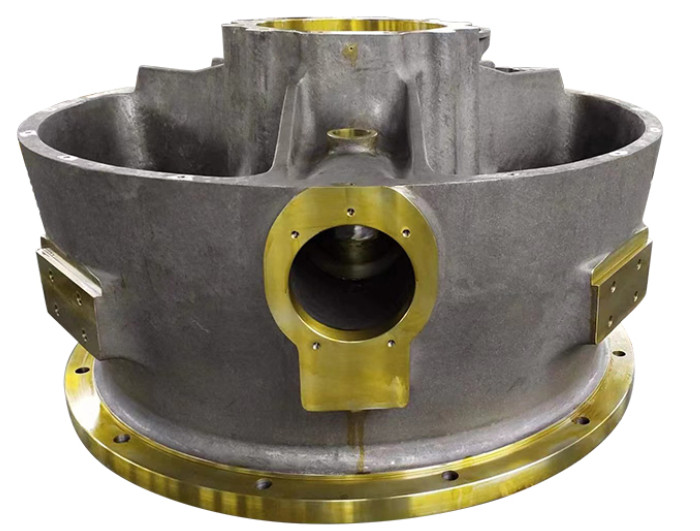

Crusher spare parts encompass a wide range of components that are integral to the proper functioning of crushers. These parts include but are not limited to concaves, mantles, jaw plates, toggle plates, bearings, and eccentric shafts. Each part serves a specific purpose and collectively ensures the smooth operation of the crusher.

Why are Crusher Spare Parts Important?

Crusher spare parts are vital for several reasons:

2.1 Enhancing Equipment Performance: The quality and condition of spare parts directly impact the performance of crushers. Well-maintained and properly functioning parts optimize crushing efficiency, productivity, and output.

2.2 Ensuring Equipment Reliability: Regular wear and tear can cause parts to deteriorate over time. By replacing worn-out or damaged components with genuine spare parts, operators can maintain the reliability and longevity of their crushers, minimizing unexpected breakdowns.

2.3 Mitigating Downtime: Crusher breakdowns can be costly, resulting in downtime and lost production. By having readily available spare parts, operators can swiftly replace faulty components, reducing downtime and ensuring smooth operations.

How to Select the Right Crusher Spare Parts?

Choosing the appropriate spare parts for crushers is crucial to their optimal performance. Factors to consider include:

3.1 Compatibility: Spare parts should be specifically designed for the make and model of the crusher. Ensuring compatibility guarantees a proper fit and function, minimizing the risk of premature failure.

3.2 Quality and Durability: Opting for high-quality spare parts manufactured with robust materials ensures longevity and reliable performance, even under demanding operating conditions.

3.3 Supplier Reputation: Selecting trusted suppliers known for their expertise and commitment to quality can help ensure the authenticity and reliability of the spare parts.

The Importance of Regular Maintenance

To maximize the effectiveness of crusher wear part optimization, regular maintenance is essential. Adequate lubrication, inspections, and timely replacements contribute to the extended lifespan of both the parts and the crusher itself. Proper maintenance practices can significantly reduce the risk of breakdowns and optimize equipment performance.

Crusher spare parts are undeniably a critical component for achieving optimal crusher performance. By understanding their importance and investing in high-quality, compatible parts, operators can enhance equipment efficiency, minimize downtime, and ultimately improve productivity. Regular maintenance further ensures the longevity of both the crusher and its spare parts, providing a reliable and cost-effective solution for industries relying on crushing equipment.